PVDF (polyvinylidenfluoride) is characterized by an excellent chemical resistance coupled with good mechanical properties. Its extremely stable structure gives the PVDF a great resistance to chemical and atmospheric agents, acids, alkalis and oils. PVDF is recognized among all fluorothermoplastic to have the maximum resistance to high-energy radiation and, immediately after PTFE, PVDF is the most weather resistant fluoropolymer.

PVDF is generally used in applications that require strength, resistance to solvents, acids, bases and a low smoke generation during a fire event.

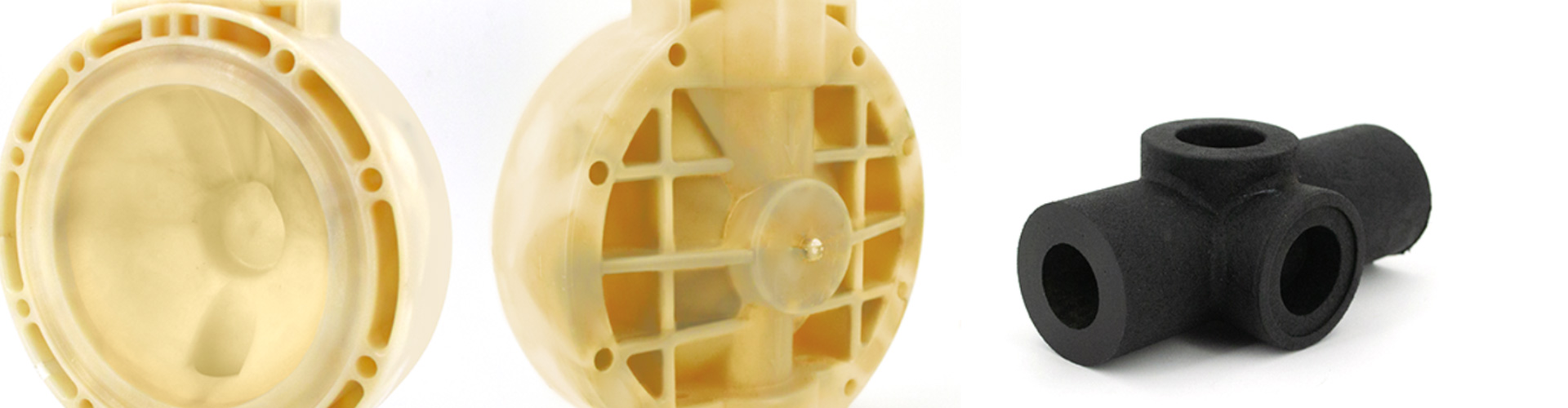

PVDF is typically applied in the chemical, pharmaceutical, food, medical and semi-conductor industry. Compared to other fluoropolymers, PVDF has an easier melt process because of its relatively low melting point. This fluorothermoplastic is suitable for the production of parts destined to chemical lining, corrosion protection and antistatic (ATEX requirements) applications, like tubes and pipes, films, containers, seals and pump, valve parts and wire coatings.

Available as unreinforced, reinforced and masterbatches, Flontech can supply both virgin and reprocessed PVDF based grades, as well as special tailormade compounds. Some of the most used PVDF compounds contain carbon fibers and special conductive carbons.

PVDF properties include:

- Relatively high continuous working temperature (150 °C).

- High chemical resistance (chemical resistance chart).

- Lower specific gravity compared to other fluorothermoplastics.

- Superior mechanical resistance compared to other fluorothermoplastics.

- Higher resistance to abrasion compared to other fluorothermoplastics.

- Good dimensional stability.

- Good electrical insulation.

- Almost zero moisture absorption.

- Good resistance to hydrolysis.

- Resistance to UV rays.

- Resistance to radiation.

| FLOMELT PVDF GRADE | COMPOSITION | PROCESS | APPLICATION |

|---|---|---|---|

| PV21 G | natural | Compression Transfer molding Injection molding Extrusion |

Chemical linings Corrosion protection Antistatic linings Stock shapes |

| PVAC41 G | antistatic | ||

| PVCFB101 G | carbon fiber | ||

| PVCFB151 G | carbon fiber | ||

| PVCF15AC41 G | carbon fiber and anistatic carbon |

| Chemical substance | |||

| Aromatic hydrocarbons |  |

|

|

| Chlorinated solvents |  |

|

|

| Cl2, dry gas |  |

|

|

| Cl2, moist gas |  |

|

|

| H2SO4, 90% |  |

|

|

| HCl, conc . |  |

|

|

| HF, 40% |  |

|

|

| HNO3, 50% |  |

|

|

| Ketones, esters |  |

|

|

| NaOCl, 15% |  |

|

|

| NaOH, 50% |  |

|

|

Recommended (not significant change in material properties)

Recommended (not significant change in material properties) Recommended under mild conditions (slightly change in material properties)

Recommended under mild conditions (slightly change in material properties) NOT Recommended (strong change in material properties)

NOT Recommended (strong change in material properties)