ETFE (copolymer of ethylene and tetrafluoroethylene) is featured by an excellent resistance to solvents, acids, radiation, impacts and high temperatures. It has outstanding chemical, thermal and electrical properties as well as a superior resistance to abrasion and cut-through.

Compared to glass, ETFE has lower weight, transmits more light and it is resilient, self-cleaning and recyclable.

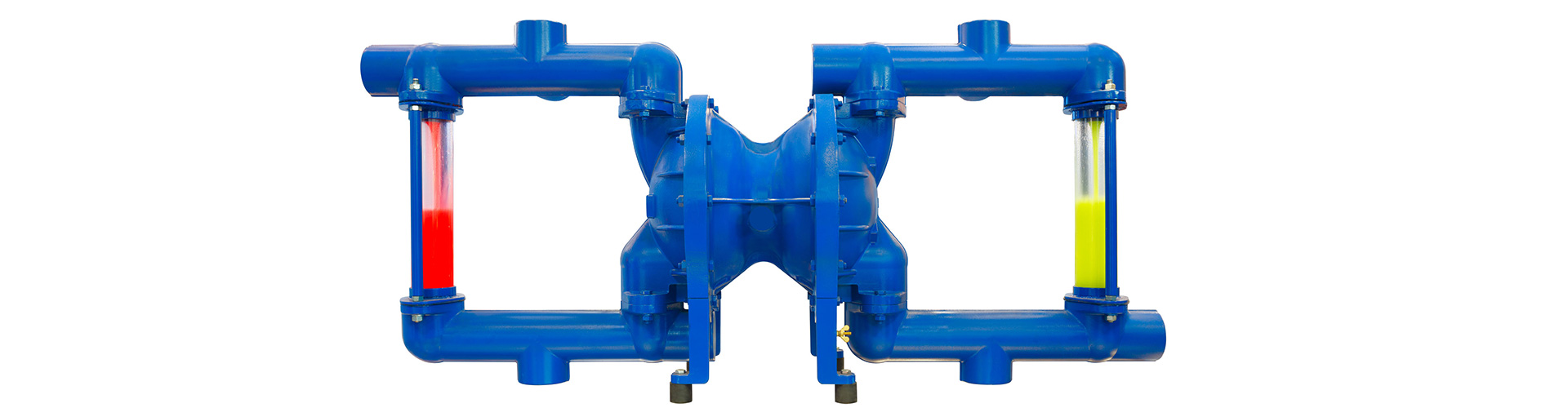

ETFE is typically applied in the aerospace, automotive and chemical industry. It is suitable for the production of extruded tubes and rounds, low permeability tubes, molded valves, radiation-resistant films for architectural applications.

Available as unreinforced, reinforced and masterbatches, Flontech can supply both virgin and reprocessed ETFE based products, as well as special tailormade compounds. Some of the most used ETFE compounds contain glass fibers and pigments.

ETFE properties include:

- Thermal resistance: both at low (-30°C) and high temperatures (+ 200°C).

- Excellent resistance to chemical, biological, radiation (cobalt) and atmospheric agents.

- High impact resistance.

- Remarkable electrical resistance and good conductive capability.

- Transparency and total permeability to UV rays.

| FLOMELT ETFE GRADE | COMPOSITION | PROCESS | APPLICATION |

|---|---|---|---|

| EC21 G | natural | Compression Transfer molding Injection molding Extrusion |

Chemical linings Corrosion protection Antistatic linings Stock shapes |

| ETGFB251 G | glass fiber | ||

| ET2RD1 G | masterbatch | ||

| ET2BL1 G | masterbatch |

Other colors masterbatches are available on request