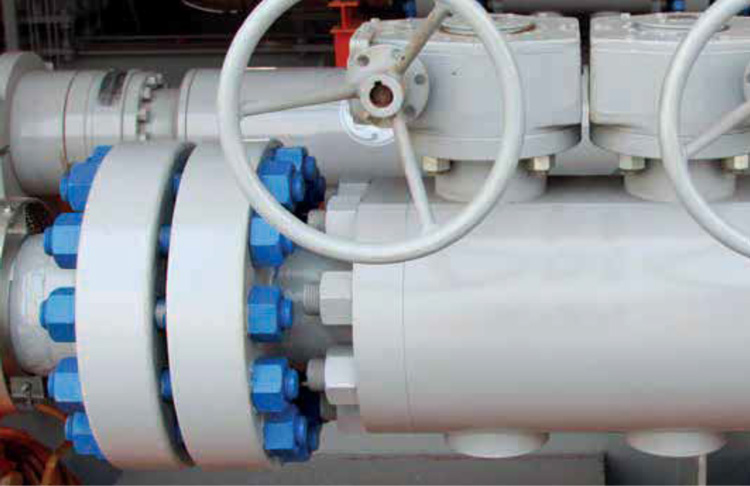

Petrochemical/Oil & Gas

Due to its strategic importance on global markets, the petrochemical/oil & gas sector influences trends, development and synergies economies. Offshore platforms and extraction wells, with all that follows in terms of transportation and storage systems, requires very high quality and reliable components. Flontech offers a wide range of products and materials specifically designed and tested for these applications.

PTFE, PEEK, PVDF, ECTFE and PFA

PTFE, PEEK, PVDF, ECTFE and PFA

Chemical

The chemical industry has driven in many cases world economies and has forcefully entered all production areas. There is no product that is not associated – directly or indirectly – with the sector of chemical transformations, which today are increasingly oriented towards productions with low environmental impact. Flontech’s range includes both products whose applications are directly linked to the reduction of harmful emissions, as well as products for the storage, containment and transport of aggressive chemical products.

PTFE, PEEK, PVDF, ETFE, ECTFE, FEP and PFA

PTFE, PEEK, PVDF, ETFE, ECTFE, FEP and PFA

Hydraulics

The control over motion transmissions through oil-hydraulics and pneumatic systems is a necessary condition for the automation of the most common industrial sectors and for everything that concerns the earth movement sector. Specifically, pressurized hydraulic systems whose dynamic components, such as pistons, require especially advanced and reliable elements in PTFE and charged PTFE, capable of withstanding very high pressures and sliding factors.

PTFE, PEEK, PVDF and PFA

PTFE, PEEK, PVDF and PFA

Industrial

The possible applications of products in PTFE cross over most industrial sectors, where certain technical characteristics of virgin PTFE are improved thanks to the use of special fillers. Specifically for application on machine tools, both as supplier of original equipments and spare parts, Flontech has developed a range of bronze-charged compounds with excellent performances in terms of compression and friction strength, factors that have made these products a huge success on all international markets.

PTFE, PEEK, ETFE, FEP and PFA

PTFE, PEEK, ETFE, FEP and PFA

Food & Pharmaceutical

In situations where foodstuff products and beverages are processed, all the components, be they part of the transformation or handling systems, must comply with international standards to ensure non-toxicity and the non-release of substances harmful to man’s health. The most common products that Flontech supplies to the foodstuff and pharmaceutical industry include materials both in virgin and compound PTFE as well as in unreinforced and reinforced Fluorothermoplastics certified for these applications.

PTFE, PEEK, PVDF, FEP and PFA

PTFE, PEEK, PVDF, FEP and PFA

Electrical/Electronics

The exponential growth of the electronics sector, and the concentrated production on special global markets, have contributed to the specialization of the components used and to the optimization of production processes. Therefore, quality and production capacity are decisive factors when it comes to supplying leading companies operating in this sector, which is especially competitive and demanding. Flontech has developed special grade compound for this high demanding sector.

PTFE, PVDF, ECTFE, FEP and PFA

PTFE, PVDF, ECTFE, FEP and PFA

Automotive/Aerospace

This high quality sector require a specific know how and process control in order to grant the needed quality final material. Flontech’s R&D and Quality departments are constantly working on new products, with the help of modern technologies for the digital and statistic control in order to guarantee supplies with “0 defects”. The same Quality criteria are adopted for aeronautical applications in an even more selective model.

PTFE, PEEK, ETFE, FEP and PFA

PTFE, PEEK, ETFE, FEP and PFA

Filters

Filters industry continuously develops products in order to obtain membranes more reliable and last life working for the most different applications fields.

In this scenario, porous PTFE take place in the most critical environments for chemicals media and physical conditions and can also be employed in either micro filtration or ultra filtration applications. With its propriety technology, Flontech is able to supply porous PTFE powder for this high specific sector and thanks to its know-how Flontech can also guide the customer through all the transformation’s steps to face and solve the problems that could come from the market.

Porous PTFE and PFA

Porous PTFE and PFA

| Flomelt fluorothermoplastics processing technologies | Flomelt PVDF | Flomelt ETFE | Flomelt ECTFE | Flomelt FEP | Flomelt PFA | Flomelt PEEK | PTFE |

|---|---|---|---|---|---|---|---|

| Injection moulding |  |

|

|

|

|

|

|

| Blow moulding | |||||||

| Transfer moulding |  |

|

|

|

|

|

|

| Rotation moulding |  |

||||||

| Extrusion |  |

|

|||||

| Compression moulding and free sintering |  |

|

|||||

| Isostatic compression moulding |  |

||||||

| Hot Compression moulding |  |

|

|

|

|

|

|

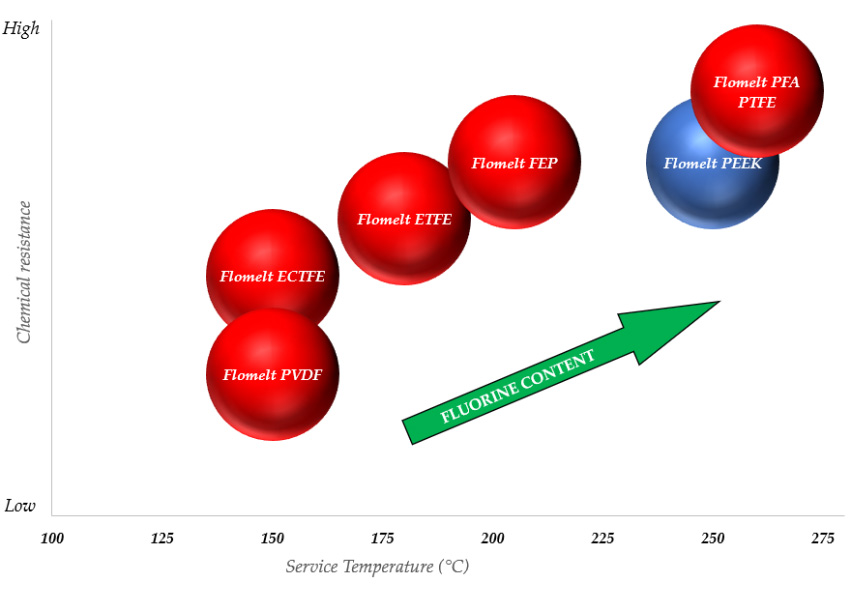

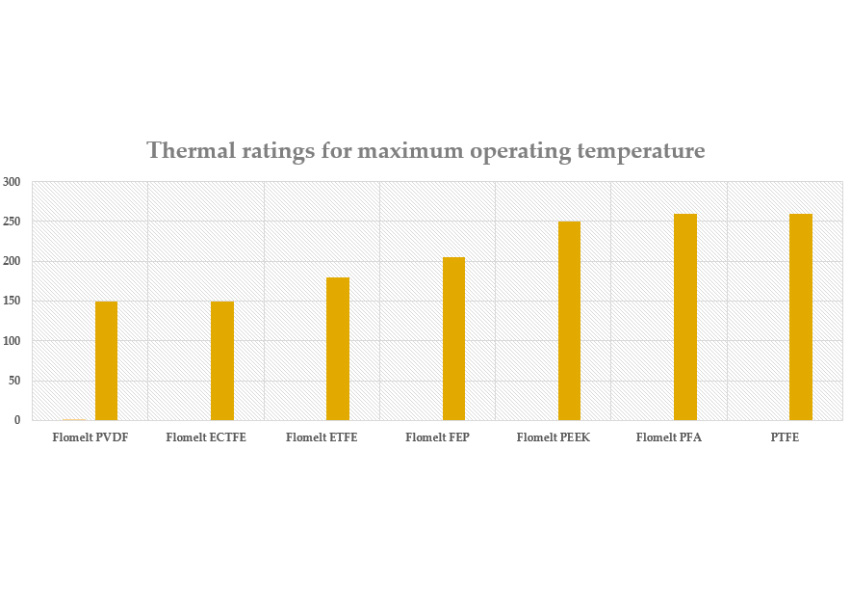

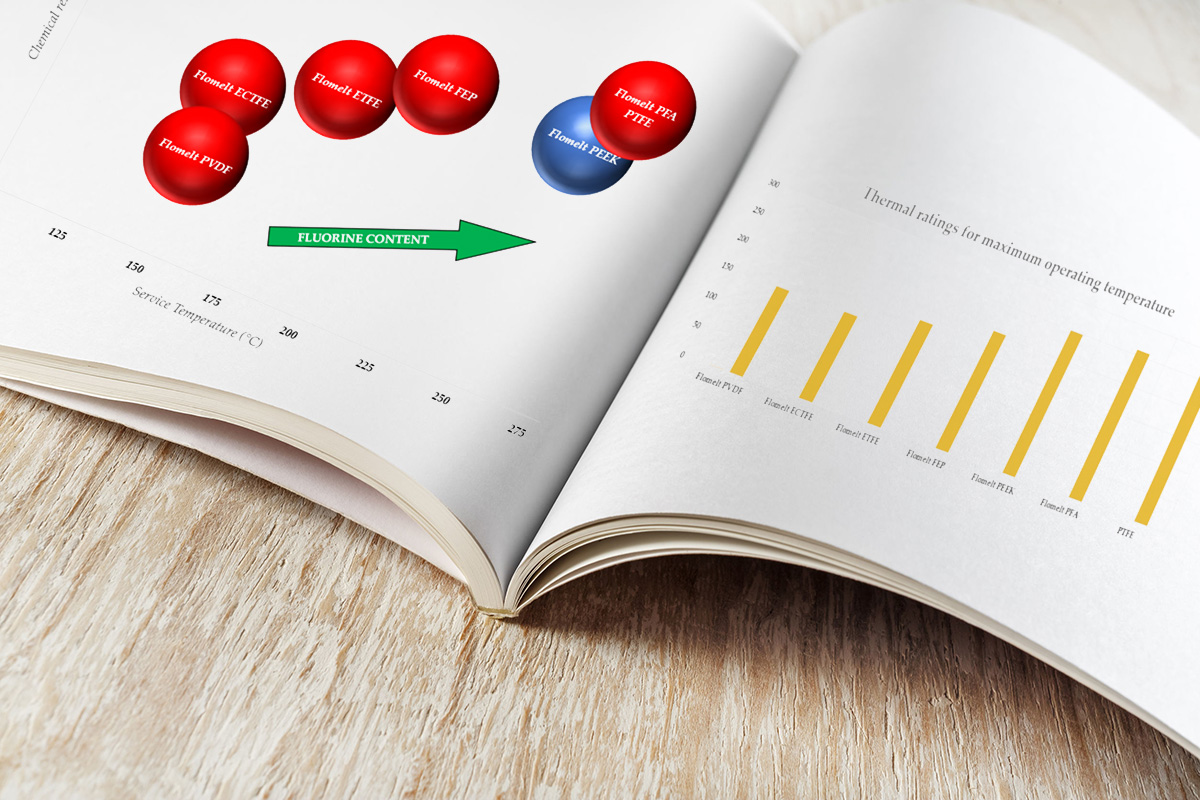

Thermal and chemical charts for Flontech's materials:

Select the materials' family you are looking for thanks to our deep knowledge on polymer performances.