ECTFE (copolymer of ethylene and chlorotrifluoroethylene) is characterized by a good combination of mechanical strength and ease of processing. It has an excellent resistance to chemical and atmospheric agents, as well as to abrasion. It also shows high resistivity, while low permeability and dielectric constant.

ECTFE is widely used in anti-corrosion applications such as linings and self-supporting constructions; its purity and surface smoothness make ECTFE the ideal product for wire and cable applications, in particular in the photovoltaic sector and in the wet-tools field.

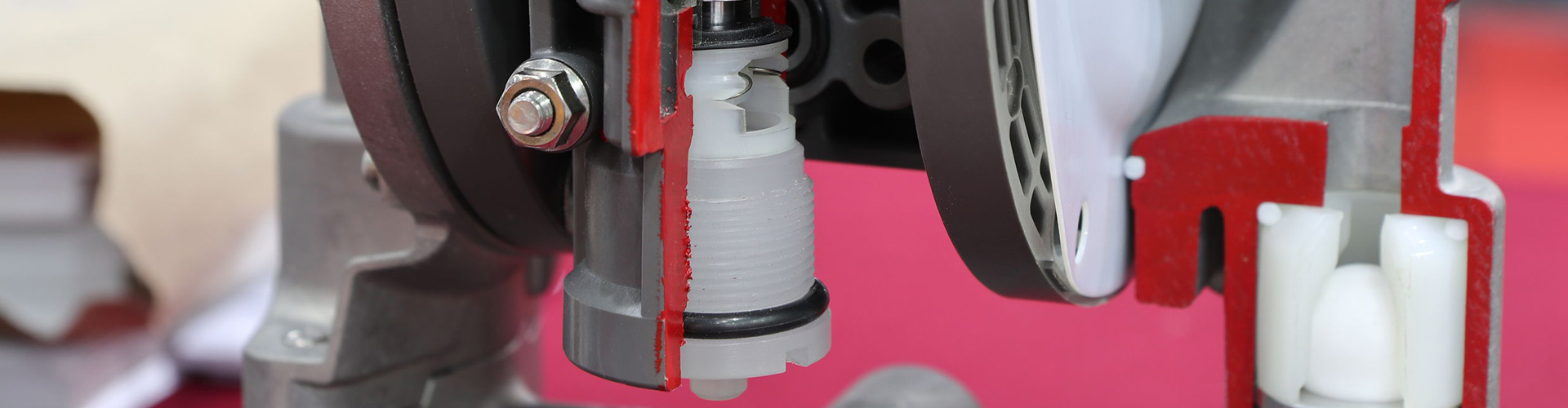

It is suitable for the production of parts in the lining process for chemical corrosion protection like valve seats and bearings and for the production of semi-conductors, wires, cables and electrical insulators.

Available as unreinforced, reinforced and masterbatches, Flontech can supply both virgin and reprocessed ECTFE based products, as well as special tailor made compounds.

ECTFE properties include:

- Resistance to high temperatures (up to + 150 ° C) even for long times.

- Good chemical resistance to most acids, bases, solvents and oils.

- Resistance to irradiation and weather activities.

- Excellent resistance to impact, abrasion and gas permeation.

- Good mechanical resistance.

- Excellent insulation characteristic.

| FLOMELT ECTFE GRADE | COMPOSITION | PROCESS | APPLICATION |

|---|---|---|---|

| EC21 G | natural | Compression Transfer molding Injection molding Extrusion |

Corrosion protection Corrosion protection Stock shapes |